- high process reliability in terms of salt, liquor ratio, temperature and time dependency

- very good reproducibility and efficiency

- high rate of fixation and short fixation time

- very good combinability resulting in uniform dyeing performance

- easy washing off even in deep shades

- high solubility in presence of electrolytes

- suitable for exhaust and continuous processes

- high fastness level

- high economy in dyeing of deep shades using Cotfix Navy NL-R.

Cotfix CL series – Dyeing Method:

Cotfix NL Series – Electronic Shade card -

Note: The shades shown in this electronic shade card are just representative and do not exactly match to actual.

We suggest the following ternary combinations for best reproducible shades:

Cotfix Yellow NL-2R

Cotfix Red NL-5B

Cotfix Blue NL-BR

Cotfix Navy NL-R

Cotfix Red NL-5B

Cotfix Blue NL-BR

Cotfix Navy NL-R

General Fastness Properties:

Fastness at 1/1 SD | N | Co | Wo |

Domestic Laundering ISO C06/C2S, 60°C | 5 | 4 | |

Domestic Laundering M&S C4A, 60°C | 5 | 4 | 5 |

Washing AATCC 2A, 49°C | 4.5 | 4 | 5 |

Washing UK Proposal ; COX resp. C08, 60°C, 12 gpl perborate + 1.8 g/L TAED | 4.5 | ||

Acid Perspiration ISO E04 | 5 | 5 | 5 |

Alkaline Perspiration ISO E04 | 5 | 5 | 5 |

Acid Perspiration M&S C7 | 5 | 5 | 5 |

Alkaline Perspiration M&S C7 | 4 | 5 | 5 |

Acid Perspiration AATCC 15 | 5 | 5 | 5 |

Mercerizing ISO X04 | 5 | 4.5 | |

Chlorinated Water ISO E03, 20 mg/L Available Cl2 | 2 |

Remarks

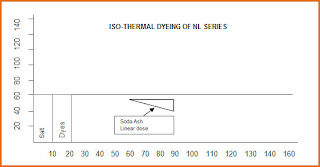

- Linear metering of Cotfix NL dyes over 15 min.

- Dispense alkali progressively over 30 min.

- In case of mercerized cotton or viscose the salt amount can be reduced by factor 0.85.

- In order to improve levelness in difficult to dye materials the starting temperature could be as high as 80°C and fixation at 60°C as indicated.

Cold-Pad-Batch:

No comments:

Post a Comment